Mining & Quarry Supplies

Buffalo Wire Works is your premier manufacturer for mining and quarry supplies, accessories and equipment for the aggregate, slag, coal, construction, recycling and mining markets. We carry a full line of conveyor parts, conveyor belting, canoe liners, idlers, pulleys, manganese crusher parts, wear parts and much more. We strive to provide our customers with what they need, offering high quality products at competitive prices.

Our engineers in the field and application specialists help our customers identify areas for improvement, correct application and load capacities to optimize resources and increase production output, all while reducing operation costs and down time.

Find out more about our mining and quarry supplies:

- Conveyor Belting

- Idlers and Pulleys

- Cone and Jaw Crusher Parts

- Canoe Liners

- Wear Parts Products

- Screen Installation Products

Conveyor Belting

Buffalo Wire Works’ conveyor belts work under abrasive and high impact conditions. This provides superior performance for a variety of applications in the mining, aggregate and recycling industries. Additionally, we have food grade belting for industrial applications.

Our engineering team works with each customer to get to know the product and the process to determine the most cost effective belt solution for their needs. We select the best conveyor belt construction, carcass and cover based on the specific requirements of the particular conveyor system, the material being conveyed and the conditions under which it operates.

Some of the basic belts we carry are 2, 3 and 4 ply belts in different thicknesses. We also carry specialized conveyor belts such as 1-ply and chevron, among others.

Our 3-ply belts are available in 3/16 x 1/16, ¼ x 1/16, 1/8 x 1/16

Our 2-ply belts are available in 1/8 x 1/16, 3/16 x 1/16

We have a wide selection of conveyor belt fasteners that include staples, hinges and plate fasteners.

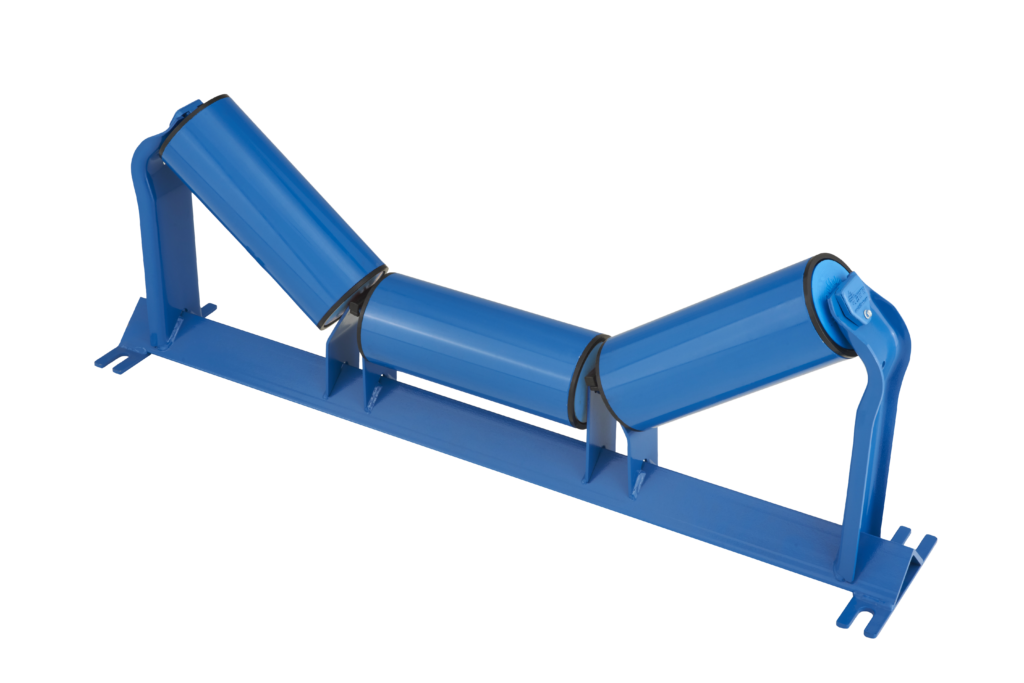

Idlers and Pulleys

Buffalo Wire Works assists each customer to identify optimum conveying solutions. Our idlers and pulleys offer high quality and durability that exceed CEMA specifications. They are interchangeable among different conveyor brands and are easy to install.

The rolls have sealed bearings that keep debris out and do not require greasing, providing a longer life to your system, reducing maintenance and down time.

| Series | A, B, C, D, E |

| Roll Diameter | 4”, 5”, 6”, 7”, 8”, and more |

| Angle | 10⁰, 15⁰, 20⁰, 35⁰, 45⁰ |

| Roll Type | Return, Troughing, Impact, and more |

| Belt width | 24”, 30”, 36”, 48”, and more |

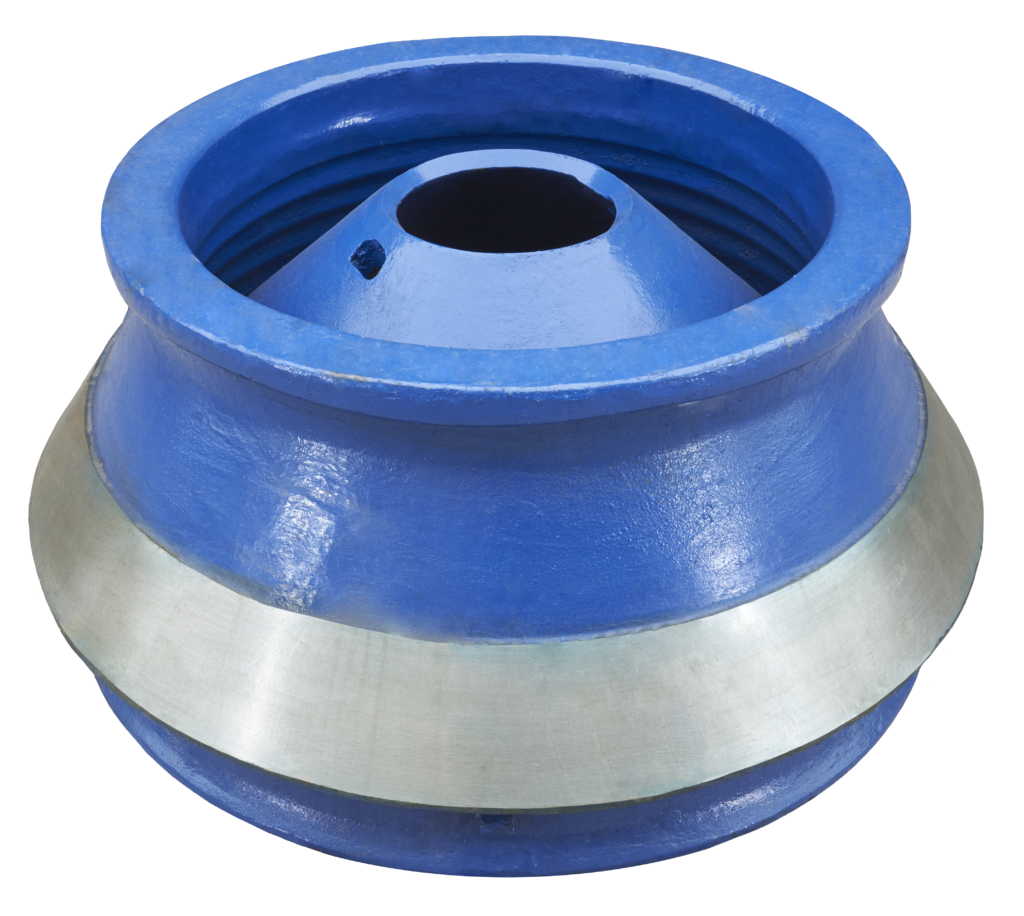

Cone and Jaw Crusher Parts

Buffalo Wire Works offers the widest variety of high quality crusher parts and accessories for the mining, aggregate and recycling industries. We offer replacement crusher parts and patterns that are fully compatible with OEM manufacturers’ styles and designs with respect to fit, form, function and performance.

We provide a guaranteed solution at a lower overall cost for plant operations:

Cone Crushers:

Bowl Liner, Mantle, Torch Ring, Feed Cone Plate, Main Shaft Nut, Main Frame Liner, Shafts, Bushings, Bearings

Jaw Crushers:

Movable and Fixed Jaw Dies, Upper and Lower Cheek Plate, Toggle Plate, Wedges

Gyratory Cone Crushers:

Mantle, Concave Ring, Burn Ring, Head Nuts

Horizontal Shaft Impactors (HSI):

Blow Bars, Impact Plates, Frame Liners

Vertical Shaft Impactors (VSI):

Feed Eye Ring, Rotor & Back-Up Tip, Tip Wear Plates, Distributor Plate, Top/Lower/Upper Wear Plates

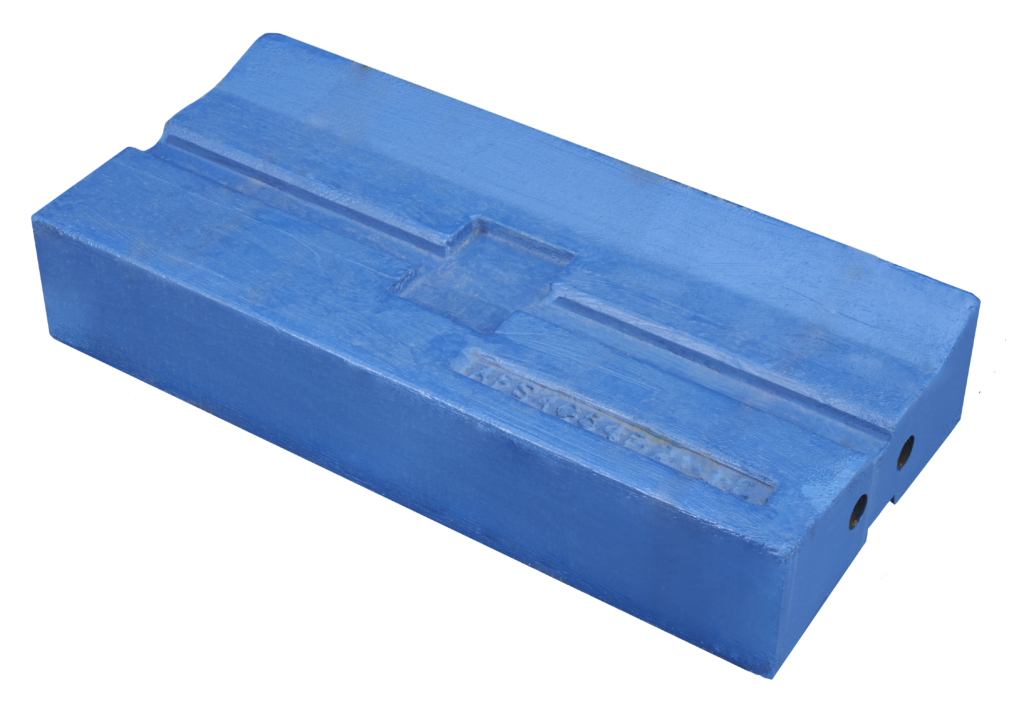

Jaw |

Cone |

Blow Bar |

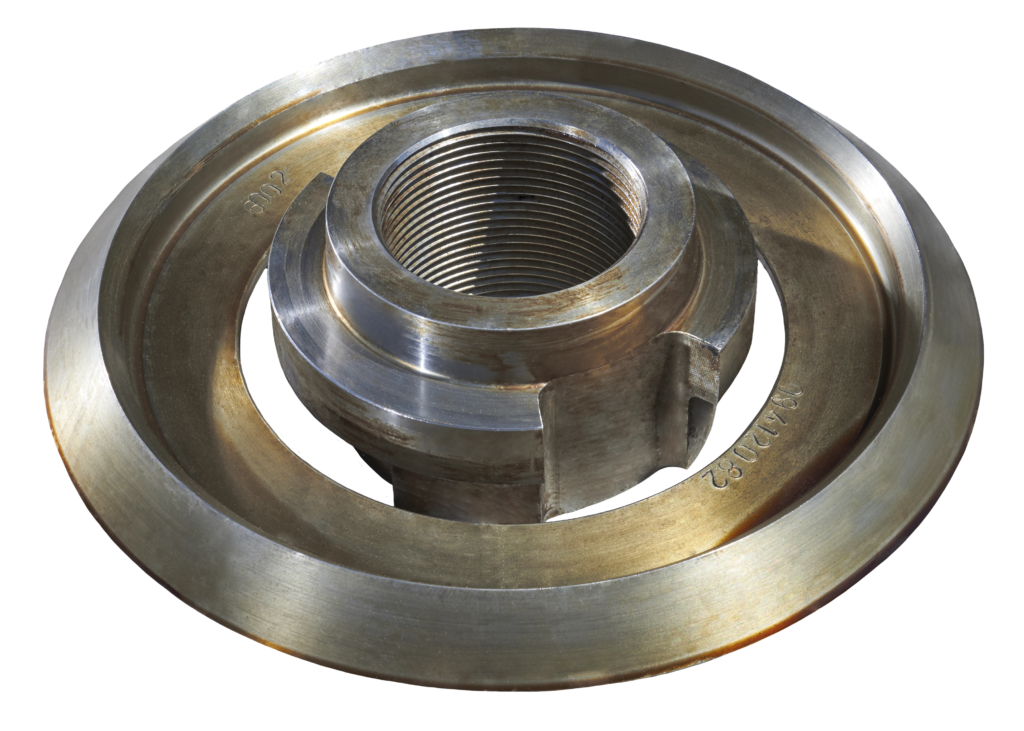

Torch Rings |

Feed Cone Plate |

Shaft Nut and Torch Ring |

Our cast products are the most resistant in the industry and are available from 14% to 21% manganese content. Our engineers in the field and in the office can help you determine the best composition material to improve in efficiency and reduce maintenance and replacement down time.

Motors, reducers, spare parts and more!

Take advantage of our motors, reducers, bushing assemblies, motor mounts, and more to complement your crushing operations. Our products perform under the harsh conditions of the rock crushing industry.

Canoe Liners

Buffalo Wire Works creates Canoe Liners made of steel and rubber to prevent the spillage of material and protect against the wear of abrasive and sharp material. The liners have a beveled edge that promotes a good seal along the inside wall. Available in different profiles and lengths for ease of installation and handling.

Wear Protection

Protect your investment. If your equipment goes down due to wear damage, you’re looking at lost production and repair costs. Buffalo Wire offers several wear parts to protect and prolong your equipment’s life and prevent unplanned downtime. We have the most cost effective and efficient product for your specific application!

Plate AR200, 400 and 500

AR plate receives impact from heavy loads and abrasive or sharp material; your equipment does not.

Typical applications for AR200 steel plate are cement mixer drums and fins, bulk material handling chute liners, skirt board liners, and screw conveyors. AR plate protects equipment against wear, although it is not for structural applications.

Typical AR plate products range from 200 to 500; for example, AR 200, AR 400, and AR 500. These numbers designate the hardness of the material in Brinell (BHN). The higher the hardness of the material, the more resistant it will be to abrasive wear.

AR400F has a nominal hardness of 400BHN. AR400F is used in equipment subject to abrasive wear, for example truck beds, crushers, hoppers, buckets, chutes, conveyor troughs, bulldozers, concrete mixer drums and excavators.

AR 200 plate is designed for general impact and abrasion applications, while AR 400F and AR 500F are designed to withstand high abrasion, low impact conditions. AR plate can be bolted down or welded onto the surface to protect. Buffalo Wire will analyze your application and recommend the most cost effective plate.

Parts available in inventory:

| Part # | Plate | Thickness | Width |

| B053758 | AR200 | 1/4″ | 48 |

| B053760 | AR200 | 3/8″ | 48 |

| B053761 | AR200 | 1/2″ | 48 |

| B053762 | AR200 | 3/4″ | 48 |

| B048150 | AR400 | 1/4″ | 48 |

| B044110 | AR400 | 3/8″ | 48 |

| B053763 | AR400 | 1/2″ | 48 |

| B053764 | AR400 | 3/4″ | 48 |

| B053765 | AR400 | 1″ | 48 |

| CHRO-001 | Chromium Overlay Plate 1/8″CC+1/4″AR | 3/8″ | 48 |

| CHRO-002 | (Chromium Overlay Plate 1/4″CC+1/4″AR | 1/2″ | 48 |

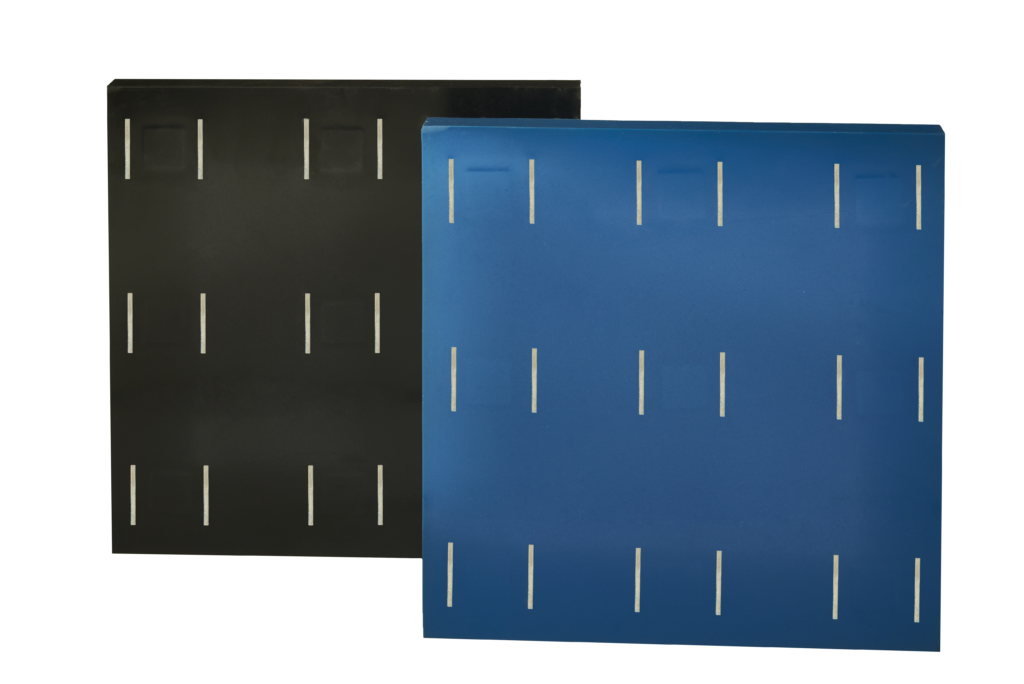

Ceramic Liners

Our High alumina ceramic liners are used in highly abrasive applications. Ceramic liners provide optimum sliding surface for bulk material handling, replacing UHMW, urethane sheets and other plastic liners that distort and wear out. Ceramic liners low coefficient of friction and stable surface provide years of maintenance-free service. The tile size, shape and layout is determined by the customers’ protection requirements.

Ceramic liners are particularly suitable for many applications like:

- Deflectors / Impact Plates

- Chutes

- Bins / Hoppers

- Skirt Liners

- Stackers & Reclaimers

In many cases, wear is caused by a combination of material impact and abrasion. Buffalo Wire offers a solution in which our high alumina ceramic is used in combination with rubber. This combination allows the ceramic to float in a shock absorbing media, providing the ultimate protection against abrasion and impact. Our in-house engineers, manufacturers and technicians in the field allow us to recommend the most beneficial solution for any given processing application.

Rubber Liners

Rubber liners solve impact problems, large and sharp material damage, and reduce noise. Rubber liners are used to cover and protect surfaces that suffer extreme impact, shredding, and abrasion. Our rubber liners also reduce mechanical fatigue and fractures and are normally used when the material is large, irregular, or sharp. Rubber liners have been successfully used to protect dozers, crushers, discharge areas, transfer of material areas and cover truck beds that receive between 10 and 400 tons of material.

Rubber reduces noise and is lighter than AR plate. Our rubber liners can last up to three times more than plate when in contact with abrasive materials and up to five times more under impact conditions.

Available in thicknesses of 1”– 5” and may have a metal backing of ¼” or 3/8”. Rubber liners can be cut to 48” x 96” or 48” x 120”, or to your own sizing needs. Available in 45 – 50A hardness for larger sized particles to withstand greater impact. 65A hardness sheets are more widely used for abrasion and smaller sized particles.

Magnetic Liners

Protecting your investment with wear parts is extremely important. Let us help you do just that with our high-quality polyurethane magnetic liners. With no bolts, adhesives, welding, cutting or retro fitting required, we guarantee a quick and easy installation. Our liners are efficient in both static and vibratory applications. Rotation is also very quick and allows one to protect high wear areas easily.

Products Offered:

· Discharge Lips

· Feed Lips

· Pan Liners

· Chute Liners

· Cross Tube Protection

· General Frame Protection

Meeting your specific needs is our ultimate goal; that is why we create custom solutions for your specifications and requirements. Buffalo Wire’s liners can be made in various shapes and designs and is also available with ceramic inserts.

Chromium Overlay Plate

Chromium Overlay Plate is intended for extreme abrasion, corrosion and impact applications. The chromium carbide wear surface is a ceramic compound that is welded to a mild steel substrate. This provides a very resistant surface that will not separate. The primary purpose of the overlay is to protect the surface it is welded to from damaging wear and tear.

Common uses include:

- Chute liners

- Hopper liners

- Wear liners for dozers and buckets

This bimetallic plate (meaning two types of metals) consists of a mild steel base plate overlaid with chromium carbide. Typically, a ceramic compound formed of 30% chrome and 5% carbon, chromium carbide metallurgically bonds to the steel, forming a protective and durable surface that will not separate from the base metal.

Chromium carbide overlay steel plate is extremely hard, resistant to both wear and impact applications and withstands high temperatures. As a result, chromium carbide plate is ideal for extreme wear applications, high temperature environments and situations where corrosive problems exist. Chromium carbide overlaid plating also offers a high level of impact resistance.

Since it is composed of a combination of high chrome and high carbon, chromium carbide steel plate achieves unparalleled hardness. When the two metals join forces, they form chromium carbide crystals that reach 600 BHN on the Brinell hardness scale. That’s five times the hardness of unplated mild steel.

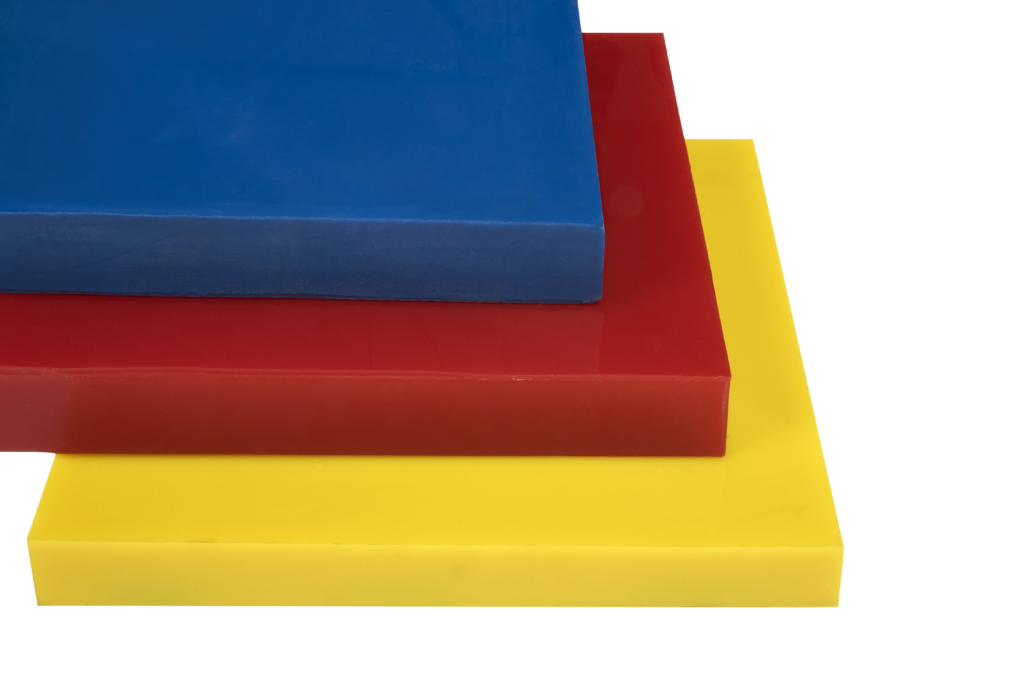

Urethane

Urethane can solve your problems of wear by abrasion under wet conditions. Urethane is not used under conditions of impact or sharp material, however it is widely used to protect surfaces that suffer extreme abrasion (not impact), typically in wet applications.

Eliminates sticking problems in hoppers, sand screw transporters, concrete mixers, silos, feeding and transport of material areas.

Urethane sheets are available in thickness of ½” – 4”. They are available in sizes 48” x 96” or 48” x 120”. They can also be cut to your specific size requirements. Available in harness 55 – 90A.

UHMW

UHMW high quality sheets promote the flow of material. With a low friction coefficient, UMHW is used best when the friction coefficient is of greater importance than wear as well as in applications where there is stickiness. Additionally, it provides protection to your equipment. UHMW is available in 65D hardness that is equivalent to 110A hardness.The UHMW virgin version offers better resistance to impact, while the recycled version offers a lower cost option for applications that are not too severe.

Available in sheets ¼” – 4” thick and 48” x 120”, or cut to your specific needs.

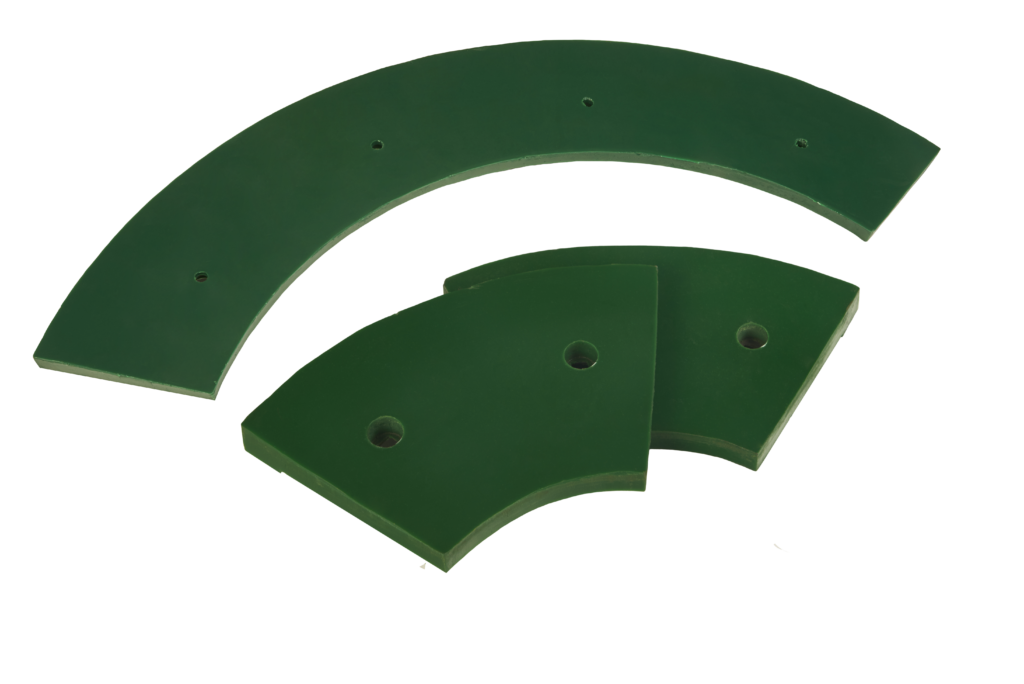

Urethane Classifier Shoes

Urethane classifier shoes can be used to cover de-watering screws, as replacement wear parts on classifiers, and screw conveyors in OEM equipment. Classifier shoes protect metal surfaces and control many of the wear problems common to bulk aggregate handlers that turn and wash moving stone. Urethane classifier shoes are wear and corrosion resistant, light weight and easy to install.

Our classifier shoes come in different styles and sizes and can either have a metal backing or metal plates for welding. Classifier shoes can be impregnated with ceramic beads for greater wear protection or fortified with metal inserts that help secure fastening.

Screen Installation Products

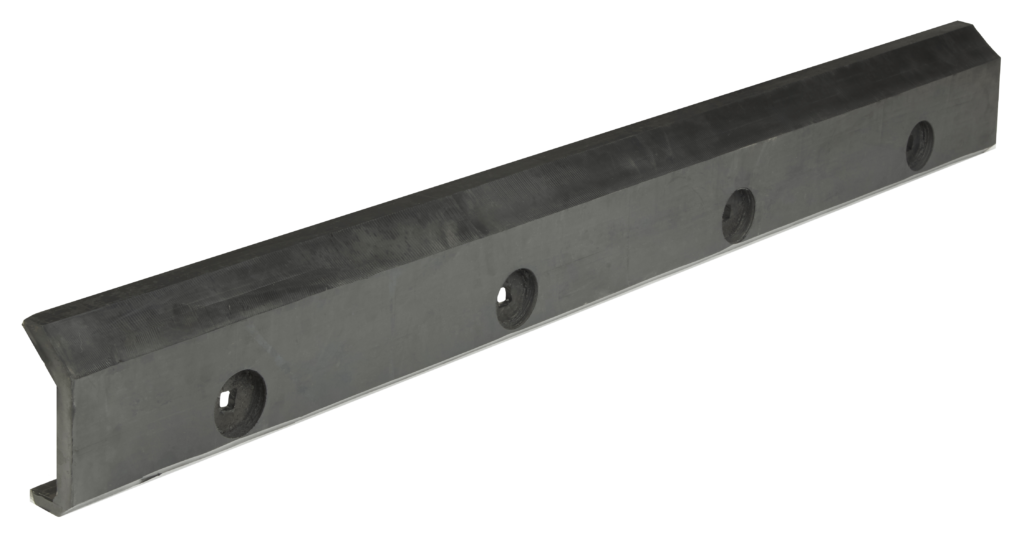

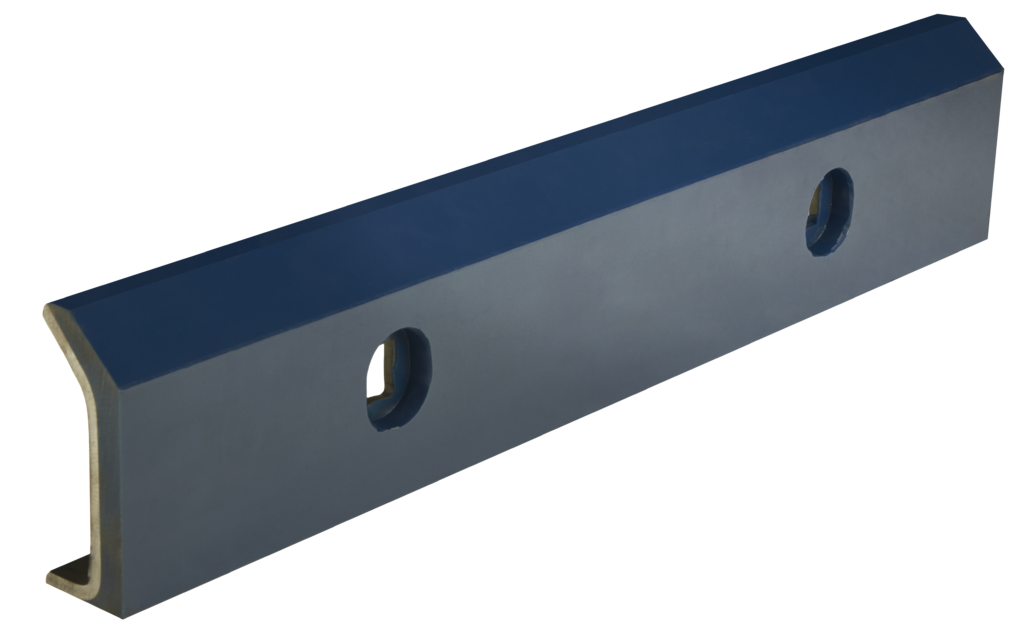

Tension rails

The right tension rails ensure proper tensioning and installation of your screens and prolong your screens’ life. An adequate tension rail matches the exact length of your screen and ensembles perfectly with your screen’s hook.

Our tension rails are available in many profiles and lengths for a perfect fit with all screener types, brands and sizes. We can even customize the hole pattern on each tension rail. Buffalo Wire’s tension rails are made from AR plate and manufactured to custom specifications, which assure the correct installation of your screens and prolongs the screens’ life. Tension rails are also available in urethane and rubber coated to dramatically extend their life.

Adjustable Pins and Wedges

The pin and wedge mounting assembly is used on vibrating screen decks to provide secure locking of the screen panels while permitting rapid assembly and disassembly of the assembled components. The pin is slotted for receipt of the wedge and the wedge has an enlarged head which is of a greater width than the pin’s slot.

Pins and wedges are a common tensioning method used on vibrating screen decks that permits for rapid screen changes compared to carriage bolts.

In abrasive applications such as mining, the head of the wedge and the pin are preferably covered with inexpensive, replaceable caps of an abrasion resistant material such as polyurethane, polypropylene or neoprene.

Carriage Bolts

Our heavy hex nuts have a plated finish and USS thread [class 28 thread fit]. Nuts are available in 1/2″, 5/8″, and 3/4″.

Our shaker screen bolts are threaded to the head and manufactured from grade #8 carbon steel. They are double heat treated to prevent stretching or breaking. Bolts are plated and available in 1/2″, 5/8″, and 3/4″ diameter in various lengths.

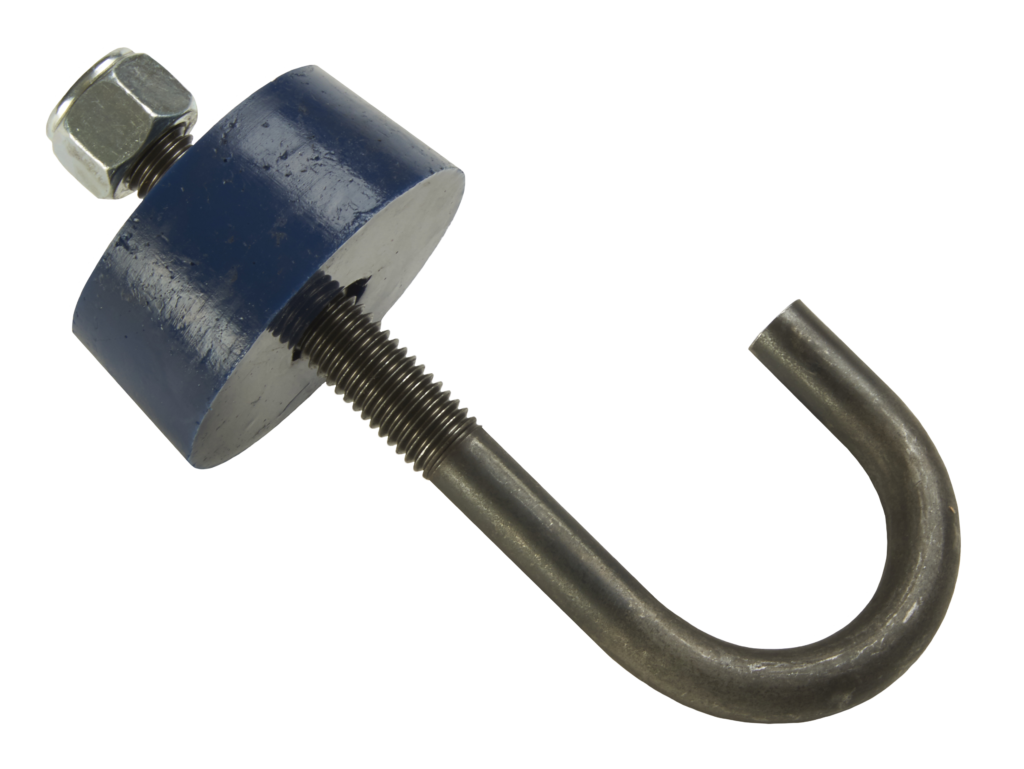

J-bolts and Donuts

J-bolts hold the screen cloth to the deck frame.

Manufactured from 2A-36 steel, these bolts ship with nut. Formed with a 1-1/4″ hook at 63″, J-bolts are available in several lengths with both 1/2″ and 5/8″ diameters.

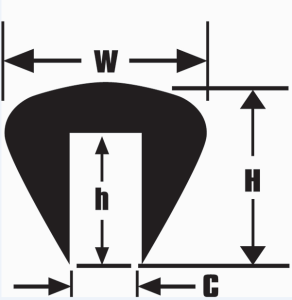

Channel Rubber

Channel Rubber absorbs the shock of impact during sizing operations. Our rubber resists cuts and tears and is weather resistant. Long legs help keep the Crown Bar Rubber from twisting out of position during operation. Our heavy-duty rubber is extra thick on top – the point of maximum wear – to provide longer wear life for your screen cloth.

Made of a high quality 60 Shore A rubber, this rubber is mounted on the support bars of screens. The capping rubber protects the support bar and also protects the underside of the screen cloth from wear. It is available in several different widths and heights to suit the different support bars on the market. Channel Rubber helps to keep the screens properly tensioned and prevents metal with metal friction that causes wear and tear.

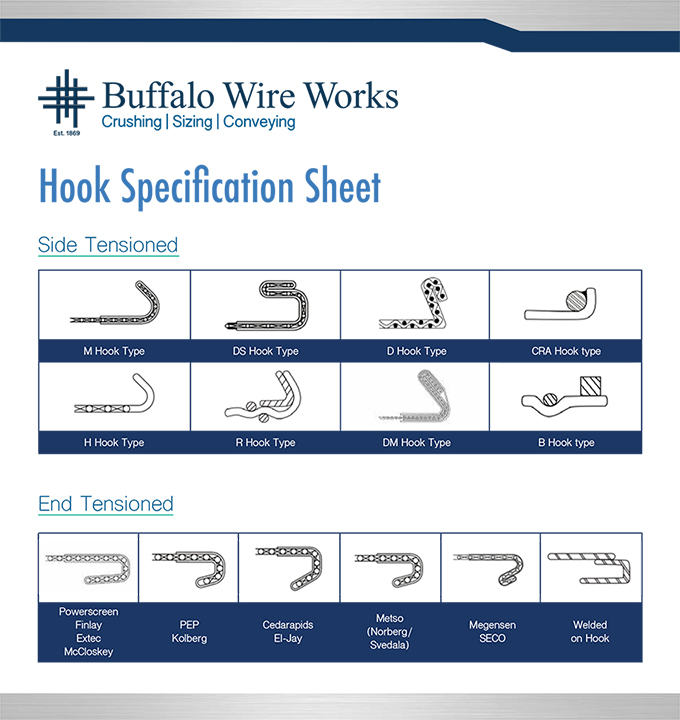

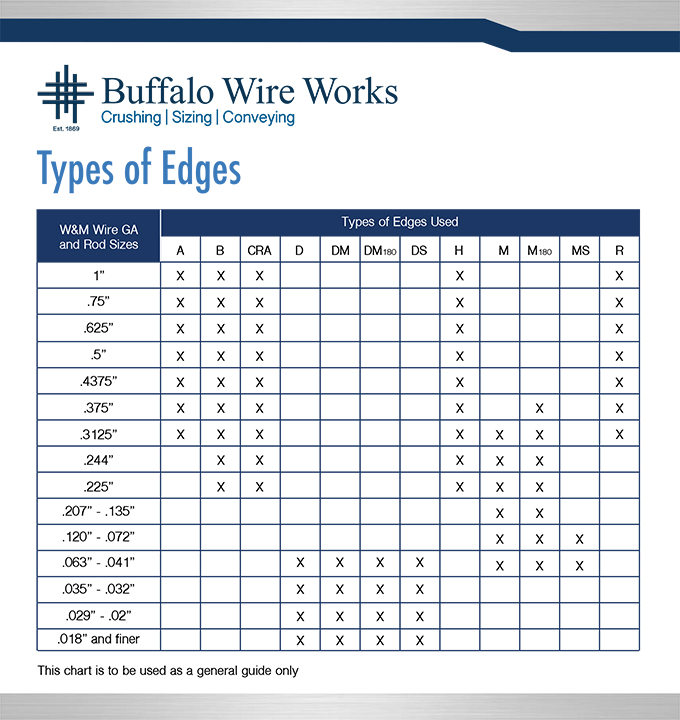

Hooks

Buffalo Wire Works offers a variety of hooks to serve your unique needs. Proper screen size and tensioning is critical for the perfect fit. All of our hooks fit OEM machines as well as customer specific designs. Depending on the wire diameter of your screen, our knowledgeable sales team will select the best hook to optimize your screen life.

For more information about our hooks and other products contact us at [email protected] or call us at 716.826.4666

Buffalo Wire Works persistently incorporates products, resources and services to help our customers achieve their best. We look forward to becoming your partner in order to help improve your overall performance and reduce your operating costs.